Depending on the type of drill bit, only Perspex/acrylic, wood, and some metals are suitable. If unsure, ask.

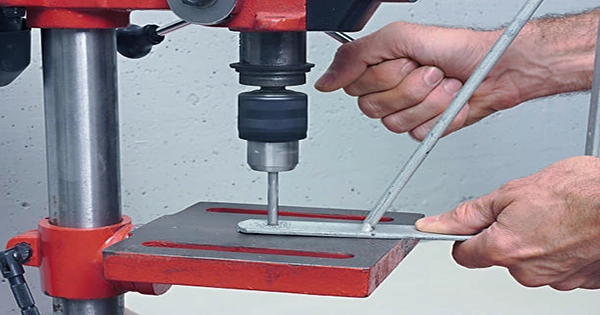

The motor-driven head of the pillar drill features a chuck that can hold bits or cutters. Additionally, the work is mounted on an adjustable table. The drill bit is lowered into the material by drawing a rotational lever, which is how it is operated. The following operational safety guidelines must be followed by everyone using the pillar drill in order to prevent mishaps.

Operational Safety Rules:

- Keep long hair tied back and avoid wearing loose garments or gloves.

- These objects will become stuck in the bit or spindle.

- Never make setup or drill press adjustments while it is operating.

- Chuck key should never be left pressed. When you are altering a little and the power is off, it should only be on the chuck.

- Always abide by the 4-inch rule.

- Don’t ever push too hard. Observe its own rate of cutting.

- Other than by holding it, work must be clamped or otherwise fastened to the table. When drilling components, don’t hold them.

- Never remove a guard without the technician’s or the WRL manager’s permission.

- Supervisor approval is required for setups requiring anything other than the basic drill press equipment.

- Before installing, always clean the drill shank, drill sleeve, and spindle hole.

- Using a drill drift and a hammer, remove tools with taper shanks from the spindle or sleeve.

- While the power is on, never attempt to release the drill chuck.

- When releasing the drill chuck or taper shank drill, lower the drill spindle nearly to the table to lessen the possibility of harm if they fall onto the table.

- Never perform maintenance on a moving machine!

- Stop the machine if the drill becomes stuck in a hole and manually turn the spindle backward to free the bit.

- To clean chips and lubricate the drill bit while drilling a deep hole, remove it frequently.

- Turning off the power should cause the spindle to stop on its own. Never attempt to use your hand to stop the spindle.

- Drilling through Plexiglas and other fragile polymers can be challenging. When drilling these materials, seek guidance from a shop specialist regarding the best drill and coolant to use.