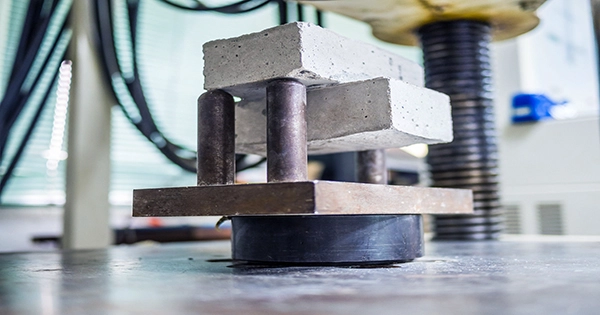

A material or structural element’s capacity to endure loads that, when applied, cause them to shrink in size is referred to as their compressive strength. A test sample is subjected to a force at its top and bottom until it breaks or deforms.

Fracturing happens when materials like concrete and rock undergo compressive strength tests, which are frequently used to analyze these materials.

Compressive strength tests can be performed on materials like steel, and deformation is frequently seen with ductile materials. A ductile material will initially adapt to the applied load by changing the internal structure of the material a process known as plastic flow.

When the distortion is localized in one place, the material fractures because the plastic can no longer flow. Tensile strength is typically the chosen indication for measuring and comparing ductile metals. This is due to the fact that tensile stress, which is better suited to the plastic flow phenomena, gauges the forces required to pull a material apart.

Corrosionpedia Explains Compressive Strength: Compressive strength is a maximum level of compressive stress that causes ductile failure (infinite theoretical yield) or brittle failure in a material (rupture as the result of crack propagation, or sliding along a weak plane). On materials, parts, and structures, compressive strength is measured. The value of uniaxial compressive stress achieved when a material totally fails is, by definition, the ultimate compressive strength.

The particular test procedures and measurement conditions have an impact on compressive strength measurements. Typically, compression strengths are provided in accordance with a particular technical standard.

Contrary to materials with strong tensile strengths, concrete and ceramics often have substantially higher compressive strengths. Tensile strengths are frequently higher than compressive strengths in composite materials like glass fiber epoxy matrix composite. Typically, tension-resistant materials are used to strengthen concrete. Concrete specifications and quality assurance procedures frequently involve concrete’s compressive strength. The objective tensile (flexural) requirements are known to engineers, and they express these needs in terms of compressive strength.

For residential concrete, compressive strength needs might range from 2,500 psi to 4,000 psi and more for commercial constructions. For some applications, higher strengths up to and surpassing 10,000 psi are required.

The compressive strength is typically much larger than the tensile strength for both brittle and ductile materials. Fiber-reinforced composites, such as fiberglass, which are robust in tension but easily crushed, are an exception to this rule. But because concrete, a particle-reinforced composite, is much stronger in compression than tension, it must be reinforced with steel rods if it is going to be subjected to tensile stresses.